尊敬的用户您好,这是来自FT中文网的温馨提示:如您对更多FT中文网的内容感兴趣,请在苹果应用商店或谷歌应用市场搜索“FT中文网”,下载FT中文网的官方应用。

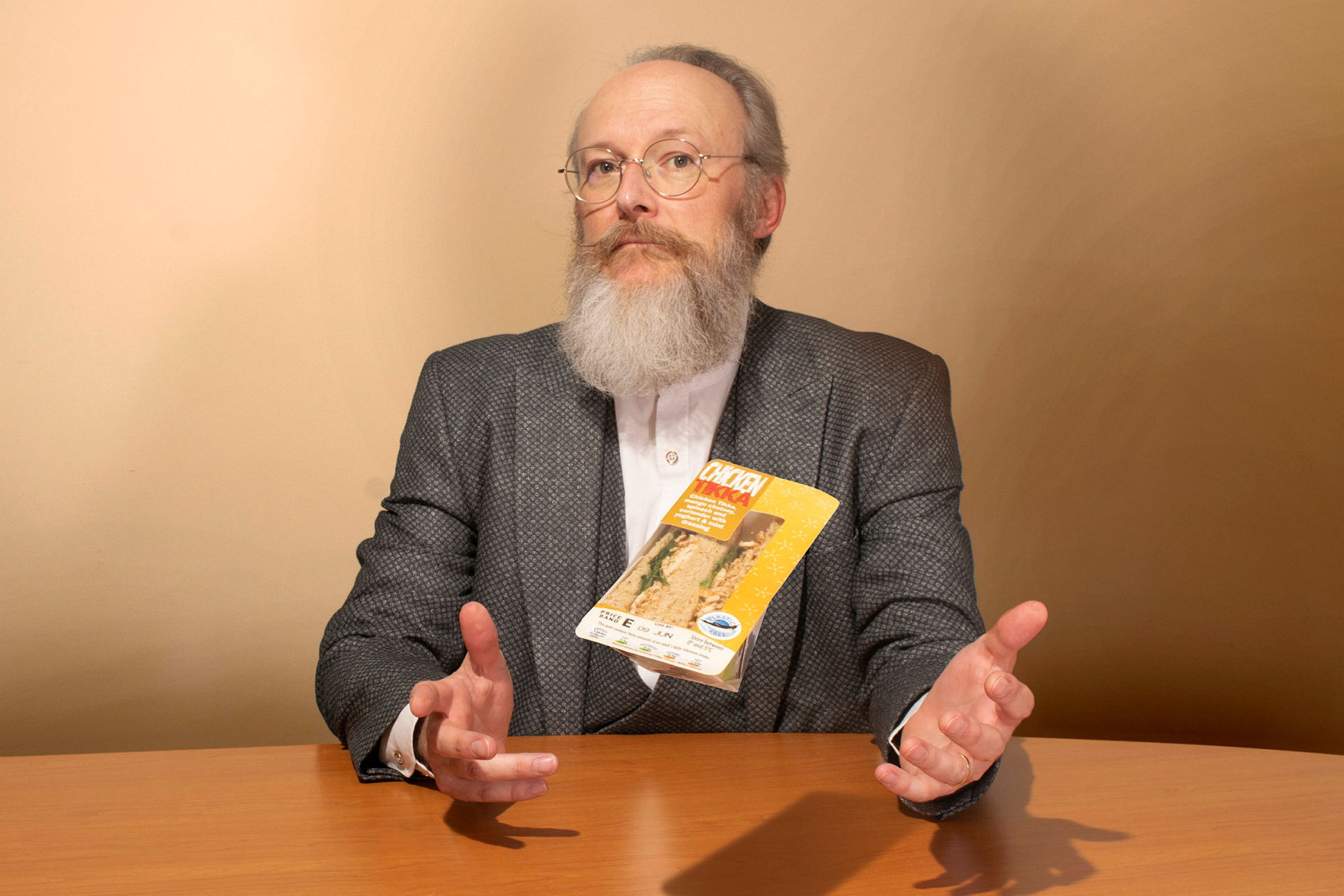

Matt Raynor is stressed. The 53-year-old chair of Raynor Foods has recently approved a £1,200 signing-on bonus for sandwich makers; tonight he will work a six-hour picking and packing shift at the company’s Essex plant because of staff shortages.

马特•雷诺(Matt Raynor)压力很大。这位53岁的雷诺食品公司(Raynor Foods)主席最近批准为三明治制作者提供1200英镑的签约奖金;今晚,由于人员短缺,他将在公司的埃塞克斯工厂进行6小时的采摘和包装工作。

“It’s been the worst two-and-a-half years of my life, with the disruption, the chaos,” he says. “We were fighting with Brexit and then Covid hit us.”

他说:“这是我人生中最糟糕的两年半,混乱不堪。我们正在与英国脱欧战斗,然后新冠病毒袭击了我们。”

Raynor’s family business, founded in 1988, makes 80,000 sandwiches a day for cafés, supermarkets, canteens and hospitals. Once a makeshift operation in his parents’ kitchen, its rise has mirrored the professionalisation of the UK’s sandwich industry over three decades.

雷诺的家族企业成立于1988年,每天为咖啡馆、超市、食堂和医院制作8万个三明治。它曾经是他父母厨房里的一个临时操作,它的崛起反映了30年来英国三明治行业的专业化进程。

Since the 1980s, a large chunk of British sandwich making has moved from kitchens and sandwich bars to chilled, hyper-efficient factories, which produce a wide variety of packaged sandwiches — from the humdrum cheese and pickle to novelty flavours involving jackfruit and plant proteins. The industry’s rapid growth was powered by rising incomes, more women joining the workforce, cheap labour from Europe and workers chasing convenience.

自20世纪80年代以来,英国的一大部分三明治制作已经从厨房和三明治棒转移到冷冻高效的工厂,这些工厂生产各种各样的包装三明治——从单调的奶酪和泡菜到新颖的口味,包括菠柚和植物蛋白。该行业的快速增长得益于收入的增加、更多女性加入劳动力大军、来自欧洲的廉价劳动力以及追求便利的工人。

Now, after the pandemic dealt the industry the worst blow in its modern history, it is being reshaped by a combination of labour shortages, souring economic conditions and changes in British working habits.

如今,在新冠疫情大流行给该行业带来了现代历史上最严重的打击后,该行业正被劳动力短缺、经济状况恶化和英国工作习惯的改变所重塑。

Chairman Matt Raynor’s parents founded Raynor Foods in 1988, and it now supplies 80,000 sandwiches a day

Raynor Foods

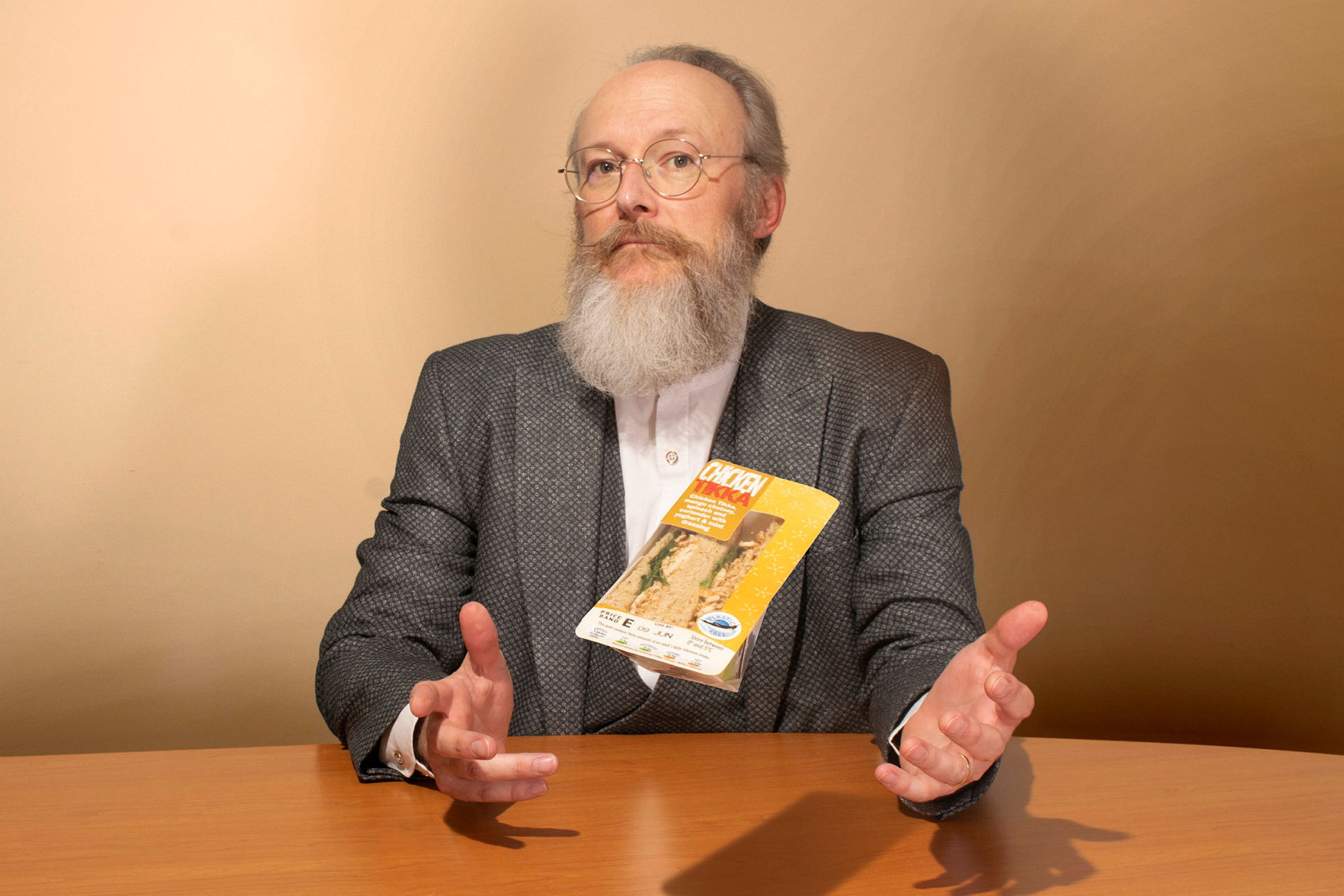

Staff at Raynor Foods work for long periods of time in cold rooms

Raynor Foods

董事长马特•雷诺的父母在1988年创立了雷诺食品公司,现在该公司每天供应8万个三明治

雷诺食品公司

雷诺食品公司的员工要在寒冷的房间里长时间工作

雷诺食品公司Before Covid lockdowns temporarily shuttered offices in 2020, people in the UK were eating £8bn worth of sandwiches a year. Kevin Moore, deputy chief executive of the UK’s largest sandwich maker Greencore, says packaged sandwiches had reached a so-called penetration of 84 per cent — meaning 84 out of 100 people bought at least one a year, a rate exceeded only by a few staples like milk and coffee, according to Kantar, a data analytics company.

2020年,新冠疫情导致办公室暂时关闭,在此之前,英国人每年吃掉价值80亿英镑的三明治。英国最大三明治制造商Greencore的副首席执行官凯文•摩尔(Kevin Moore)表示,包装三明治的所谓渗透率达到了84%——数据分析公司凯度(Kantar)的数据显示,这意味着每100个人中就有84人每年至少购买一份,只有牛奶和咖啡等几种主食的销量超过了这一比例。

But the rise of homeworking during the pandemic seems to have driven lasting changes in the routines of the industry’s most important customers: office workers. The British Sandwich & Food to Go Association estimates that, two years on, business is still 20 per cent below pre-pandemic levels.

但疫情期间在家办公的兴起,似乎推动了该行业最重要客户——办公室职员——日常生活的持久变化。英国三明治与食品协会(British Sandwich & Food to Go Association)估计,两年过去了,业务仍比疫情前水平低20%。

At the same time, the sector is facing disruption to its supply of cheap labour and ingredients. Brexit closed the UK’s doors to free movement of EU citizens, meaning production workers are scarce and their wages are rapidly rising. Intense inflationary pressure is adding to the unpredictability of purchasing and supply chain hold-ups since Russia invaded Ukraine this year.

与此同时,该行业的廉价劳动力和原料供应也面临中断。英国退欧关闭了欧盟公民自由流动的大门,这意味着生产工人稀缺,他们的工资正在迅速上涨。自今年俄罗斯入侵乌克兰以来,巨大的通胀压力加大了采购和供应链中断的不可预测性。

“I’m concerned for the whole industry,” says Raynor.

“我为整个行业感到担忧,”雷诺说。

Just in time

及时送到

While the sandwich is not about to vanish from British culinary life, the industry fears its pre-pandemic golden age, marked by low cost and seemingly infinite variety, may never return.

虽然三明治不会从英国的烹饪生活中消失,但该行业担心,大流行前的黄金时代可能永远不会回来了,其特点是成本低,种类似乎无穷无尽。

When Raynor’s parents moved from running a restaurant to making sandwiches 34 years ago “there was no sandwich industry”, he recalls. His father met the buyer for a group of Co-Op stores at a networking event, who said they needed a sandwich supplier. The kitchen operation began.

雷诺回忆说,34年前,当他的父母从经营一家餐厅转到制作三明治时,“当时还没有三明治行业”。他的父亲在一次社交活动上遇到了一个Co-Op门店群的买家,买家说他们需要一个三明治供应商。厨房的运作开始了。

“It took us nine and a half hours to make 350 sandwiches . . . we had to grill the bacon and boil the eggs, do everything from scratch,” Raynor says. “They were beautiful sandwiches,” he adds wistfully.

“我们花了九个半小时做了350个三明治……我们不得不烤熏肉、煮鸡蛋,一切从零开始,”雷诺说。“它们是很漂亮的三明治,”他渴望地补充道。

Today, making sandwiches is a precision business requiring frenetic backstage activity. At Pret A Manger, the sandwich chain that has become synonymous with London commuting life over more than three decades, sandwich-making starts in-store at 5am each day. Elsewhere, production lines work frantically during evenings and nights.

如今,做三明治是一项精密的工作,需要疯狂的后台活动。在30多年来已成为伦敦通勤生活代名词的三明治连锁店Pret A Manger,每天早上5点开始制作三明治。在其他地方,生产线在晚上和深夜疯狂地工作。

At the south London plant of Simply Lunch, a manufacturer with 290 staff, making a bacon, lettuce and tomato sandwich requires 17 stations on the production line. The orders — between 400,000 and 450,000 of them each week — come in just 48 hours before the sandwiches need to be on shelves.

在伦敦南部的Simply Lunch工厂,一家拥有290名员工的制造商,制作一个培根、生菜和番茄三明治需要在生产线上设置17个站点。每周有400,000到450,000份订单,这些订单在三明治需要上架的48小时前就已经到货。

Workers in protective gear operate in rooms where the temperature hovers at around 2C, processing 25,000 loaves of bread a week and two tonnes of tomatoes. Fifteen people are dedicated to food safety. The facility operates 20 hours a day, with the remaining four spent on cleaning. Hermann Dokoui, a shift manager at the plant, says the 9pm to 7am night shift is the hardest “because you are always walking around”, preparing for deliveries to leave the factory.

穿着防护服的工人在温度徘徊在2℃左右的房间里操作,每周加工25,000个面包和2吨番茄。有15人专门负责食品安全。该设施每天工作20小时,其余4小时用于清洁。该厂的轮班经理赫尔曼-多库伊(Hermann Dokoui)说,晚上9点到早上7点的夜班是最辛苦的,“因为你总是在走来走去”,为交货离厂做准备。

The need for freshness means sandwiches cannot be made overseas. “The sandwich industry has transformed short shelf-life, chilled distribution in the UK dramatically,” says Jim Winship, director at the BSA. “You have production plus two days or three at most. That means they’ve got to get from the factory, which might be in the Midlands, to the retail shop, which might be in Inverness somewhere, and sell it within two days.”

对新鲜的需求意味着三明治不能在海外制作。BSA董事吉姆•温希普(Jim Winship)表示:“三明治行业大幅改变了英国保质期短、冷藏配送的模式。你最多有2到3天的制作时间。这意味着他们必须从位于中部的工厂,到位于因弗内斯某处的零售商店,并在两天内售出。”

Simply Lunch’s lettuce leaves are picked in Kent in the small hours, reach the factory at 9am, pass through a sanitising chemical solution, spin in a giant salad spinner and are inside sandwiches from noon. Ultrasonic blades cut the bread. Finished sandwiches are weighed to check the protein allocation. Samples go to laboratories daily to check for bacterial contamination.

Simply Lunch的生菜叶子是凌晨在肯特郡采摘的,早上9点到达工厂,经过消毒化学溶液,在一个巨大的沙拉旋转器中旋转,然后放在中午的三明治里。超声波刀片切面包。完成的三明治会被称重以检查蛋白质的分配。样本每天被送到实验室检查细菌污染情况。

When a production line changes from one product to another, the procedure resembles a “Formula One pit stop”, says Sam Page, Simply Lunch managing director. “There is a lot of technical knowledge that goes into a sandwich.”

当生产线从一种产品转换到另一种产品时,程序类似于“一级方程式赛车的进站”,Simply Lunch的总经理萨姆•佩奇(Sam Page)说。“一个三明治里有很多技术知识”。

That precision has been tested by a dwindling supply of labour since Brexit. Page’s factory has around 40 vacancies. Another headache is the sheer pace of inflation. This year egg prices have risen by 30 per cent, mayonnaise by 80 per cent as vegetable oil prices spiked, and bread prices by 25 per cent, says Adam Newland, managing director at Raynor Foods. Now the headache is cheese, where prices have risen 76 per cent in a year to £6 a kilo.

自英国退欧以来,劳动力供应不断减少,这一精确度受到了考验。佩奇的工厂大约有40个职位空缺。另一个令人头疼的问题是通货膨胀的速度。雷诺食品董事总经理亚当•纽兰(Adam Newland)表示,今年以来,鸡蛋价格上涨了30%,随着植物油价格的飙升,蛋黄酱价格上涨了80%,面包价格上涨了25%。现在让人头疼的是奶酪,其价格在一年内上涨了76%,达到每公斤6英镑。

“There are forecasts that it will be going for £8 a kilo by year-end. Cheese is still incredibly volatile,” Newland said. Despite some commodity prices going into reverse, “nothing has eased for us,” he says.

“有预测称,到今年年底,它的价格将达到每公斤8英镑。奶酪仍然非常不稳定,”纽兰说。他表示,尽管一些大宗商品价格出现逆转,但“对我们来说,一切都没有缓解。”

Ingredient shortages caused by supply chain disruption are forcing manufacturers to adapt constantly, says Winship. Most have cut their ranges to streamline production. Greencore reduced its number of products by one-quarter after the onset of Covid-19 and it remains about a fifth below pre-pandemic levels. Simply Lunch cut its offering from 150 items to 100.

温希普说,供应链中断导致的原料短缺迫使制造商不断适应。大多数公司都削减了生产范围以提高生产效率。Greencore在新冠疫情爆发后将产品数量减少了四分之一,目前仍比大流行前水平低约五分之一。Simply Lunch将供应的商品从150种减少到100种。

Government support enabled most sandwich makers to survive the pandemic, but Southall-based Adelie Foods entered administration in 2020 with the loss of 2,000 jobs. Now Winship estimates the industry is operating at about 80 per cent of pre-pandemic sales, or £6.4bn a year.

政府的支持使大多数三明治制造商在大流行中幸存下来,但总部位于Southall的Adelie食品公司在2020年进入破产管理,失去了2000个工作岗位。现在,温希普估计,该行业的销售额约为大流行前的80%,即每年64亿英镑。

He had hoped for a full bounceback in 2022, but after the onset of rapid inflation this year, he is not so sure.

他曾希望在2022年实现全面反弹,但在今年开始出现快速通货膨胀后,他就不那么确定了。

Follow the skyscraper

跟着摩天大楼走

The success of the British sandwich industry over the past four decades belies both the precariousness of its business model and the intensity of the competition between manufacturers. Margins are inevitably tight when speed and convenience are king.

英国三明治行业在过去40年里的成功掩盖了其商业模式的不稳定性和制造商之间竞争的激烈程度。当速度和便利性为王时,利润空间不可避免地紧张。

Marks and Spencer introduced its first packaged sandwich — salmon and tomato — in 1980. Pret A Manger was founded in its current form in 1986. Greencore emerged from the 1991 privatisation of Irish Sugar.

玛莎百货在1980年推出了第一款包装三明治——三文鱼加番茄。Pret A Manger成立于1986年。Greencore诞生于1991年爱尔兰糖业(Irish Sugar)的私有化。

The broader national climate favoured sandwiches. British prime minister Margaret Thatcher’s labour reforms of the 1980s provided sandwich makers with “relatively low-paid workers”, says David Edgerton, professor of modern British history at King's College London. The white-collar ethos became one of “people working harder, with not much time”.

更广泛的国家气候有利于三明治的发展。英国首相玛格丽特-撒切尔(Margaret Thatcher)在20世纪80年代的劳工改革为三明治制造商提供了“相对低薪的工人”,伦敦国王学院的英国现代史教授大卫•埃杰顿(David Edgerton)说。白领阶层的风气变成了“人们更努力地工作,却没有多少时间”。

As food writer Bee Wilson notes in her book Sandwich: A Global History: “No dish has a stronger association with the world of work.” For employees without a subsidised workplace canteen, sandwiches became a cheap, efficient way of outsourcing lunch. “Instead of communal eating, it [became] a solitary activity,” says Edgerton.

正如美食作家比·威尔逊(Bee Wilson)在她的《三明治:全球历史》(Sandwich: A Global History)一书中所指出的那样:“没有一道菜比三明治与工作世界的联系更紧密了。”对于没有补贴的工作场所食堂的员工来说,三明治成了一种廉价、高效的外包午餐方式。埃杰顿说:“这不再是一起吃饭,而是变成了一项单独的活动。”

Today, in real terms, average household disposable income is double that of 1980, says Jon Boys, economist at the Chartered Institute of Personnel and Development. “Extra income means more stuff. Tasks like making sandwiches have switched from home production to the market economy — as have many other things over the years: childcare, cleaning, shopping.”

英国特许人事与发展协会(Chartered Institute of Personnel and Development)经济学家博伊斯(Jon Boys)说,按实际价值计算,如今家庭平均可支配收入是1980年的两倍。“额外的收入意味着更多的东西。像做三明治这样的工作已经从家庭生产转向了市场经济——正如多年来许多其他事情一样:育儿、清洁、购物。”

Oriel Sullivan, professor of sociology of gender at University College London, says the 1980s were when “female full-time employment rates really started to rise rapidly. There were fewer women at home to make sandwiches for others, and they were too busy to make them for themselves.”

伦敦大学学院(University College London)性别社会学教授奥里尔·沙利文(Oriel Sullivan)表示,上世纪80年代是“女性全职就业率真正开始迅速上升的时期”。在家给别人做三明治的妇女很少,她们太忙了,没有时间给自己做。”

The ready-made sandwich became emblematic of the era’s economic shifts. Boys says: “What are you buying? A sandwich, yes, but really you are buying time, convenience, consistency and perhaps variety too.” The brand that summed up that change was Pret A Manger, whose previous chief executive’s motto was to “follow the skyscraper”.

现成的三明治成为那个时代经济转变的象征。博伊斯说:“你在买什么?一个三明治,是的,但实际上你买的是时间、方便、一致性,也许还有多样性。”最能体现这一变化的品牌是Pret A Manger,其前任首席执行官的座右铭是“追随摩天大楼”。

With few barriers to entry for manufacturers, the market soon became intensely competitive. “Retailers have moved their contracts around and kept margins low,” says Andy Searle, managing director at consultancy AlixPartners.

由于制造商进入市场的障碍很少,市场竞争很快就变得非常激烈。咨询公司艾睿铂(AlixPartners)董事总经理安迪•塞尔(Andy Searle)表示:“零售商调整了合同,将利润率保持在较低水平。”

A ready supply of cheap and pliable labour enabled that strategy. After the EU expanded in 2004, many vacancies were filled by eastern Europeans who were willing to work long hours for lower pay. By 2017, EU nationals accounted for more than one-third of the food industry workforce, according to the Food and Drink Federation. They were disproportionately working on production lines, say industry executives.

现成的廉价和灵活的劳动力供应使这一战略成为可能。2004年欧盟扩张后,许多职位空缺由东欧人填补,这些人愿意以较低的工资长时间工作。根据食品和饮料联合会(food and Drink Federation)的数据,到2017年,欧盟国民占食品行业劳动力的三分之一以上。行业高管表示,他们在生产线上工作的比例非常高。

When it came, Brexit was accompanied by an offer of long-term settlement for existing European residents. But a points-based immigration regime introduced from 2021 stopped the free flow of low-paid labour, while the Covid pandemic prompted an estimated 1.3m overseas workers to head home.

在脱欧的同时,欧盟还为现有欧洲居民提供了长期解决方案。但从2021年开始实施的积分移民制度阻止了低薪劳动力的自由流动,而新冠疫情则促使约130万海外工人回国。

That led to an intensive recruitment drive. Pret, Greggs and other takeaway chains have suffered staff shortages after making redundancies or furloughing workers during lockdowns. Pret, which increased headcount by 28 per cent between January and April this year, has raised wages twice since September. Sandwich executives say Amazon warehouses can easily poach their employees.

这导致了密集的招聘活动。Pret、Greggs和其他外卖连锁店在封锁期间裁员或让员工休假后,遭遇了员工短缺的问题。今年1月至4月,Pret将员工人数增加了28%,自去年9月以来已两次加薪。三明治公司的高管表示,亚马逊的仓库可以很容易地挖走他们的员工。

With post-Brexit immigration policy shaped around a “high-wage economy”, ministers have pushed food manufacturers to automate rather than employ low-paid workers. But it is a major challenge to replace the dexterity of human fingers when handling irregular ingredients such as lettuce.

由于英国退欧后的移民政策围绕着“高工资经济”形成,大臣们已敦促食品制造商实现自动化,而不是雇佣低收入工人。但在处理生菜等不规则食材时,如何取代人类手指的灵活性是一个重大挑战。

Simply Lunch is investing £25,000 in a “depositor” to drop egg mayonnaise or a similar mix on to bread. Another robot drops the final slice of bread to “lid” a sandwich. Greencore already uses both devices, along with a butter spreader.

Simply Lunch公司正在投资25,000英镑购买一个“存放器”,将鸡蛋蛋黄酱或类似的混合物放入面包中。另一个机器人将最后一片面包丢入三明治的“盖子”中。Greencore公司已经使用了这两个设备,以及一个黄油涂抹器。

Raynor Foods has a robotics programme with Dutch group IRS, but it has yet to juggle multiple ingredients — a task Raynor compares with Tetris, the video game. His company has been battling vacancies and staff turnover despite raising entry-level wages by 15 per cent in a year and ramping up bonuses. Of one group of 17 new recruits, four dropped out within two days.

雷诺食品公司与荷兰IRS集团合作开展了一项机器人计划,但它还没有处理多种成分的能力--雷诺将这项任务与视频游戏俄罗斯方块相提并论。他的公司一直在与职位空缺和员工流失作斗争,尽管在一年内将初级工资提高了15%并增加了奖金。在一组17名新员工中,有4人在两天内退出了。

“We are asking people to do a physical job in a cold room without any windows, for long periods of time,” he says, adding wryly: “The glamour of the industry is not at the coal face.”

“我们让人们长时间在没有窗户的寒冷房间里做体力活,”他说,并苦笑着补充道:“这个行业的魅力不在于采煤面。”

End of the cheap food era

廉价食品时代的结束

The greater challenge may be getting consumers to return to their pre-pandemic lunching habits. Food perks are one way to entice staff back into the office but, for many, a sandwich will not cut it, says Julie Ennis, chief executive of UK and Ireland corporate services at caterer Sodexo: “People are looking for something different . . . People aren’t coming into the office for a ham sandwich,” she says.

更大的挑战可能是让消费者回到疫情前的午餐习惯。餐饮企业索迪斯(Sodexo)英国和爱尔兰企业服务首席执行官朱莉•恩尼斯(Julie Ennis)表示,食物补贴是吸引员工重返办公室的一种方式,但对许多人来说,一块三明治是不够的:“人们在寻找不同的东西……人们来办公室可不是为了吃火腿三明治,”她说。

Food delivery apps have increased consumers’ expectations of choice. Matt Ephgrave, managing director at Just Eat for Business, says the past six months have prompted “unprecedented demand” for food deliveries to offices. “We’re seeing a massive shift towards healthy options — Japanese, Poke bowls and salads,” he says.

外卖应用增加了消费者对选择的期望。Just Eat for Business董事总经理马特•埃夫格雷夫(Matt Ephgrave)表示,过去6个月,对办公室食品配送的需求“前所未有”。他说:“我们看到人们对健康选择的巨大转变——日本菜、Poke碗和沙拉。”

And in recent months, some of the major economic trends that helped fuel the sandwich boom have gone into reverse. The Bank of England has warned of the worst squeeze on disposable incomes in 30 years. The resulting cost of living crisis is expected to have far-reaching effects on British lifestyles.

最近几个月,推动三明治热潮的一些主要经济趋势出现了逆转。英国央行警告称,可支配收入将面临30年来最严重的紧缩。由此产生的生活成本危机预计将对英国人的生活方式产生深远影响。

Some manufacturers are handling the price pressure by quietly cutting portion sizes, says Andrew Walker, former chief executive of sandwich chain Eat. Raynor has pushed up prices for its customers by as much as a quarter.

三明治连锁店Eat前首席执行官安德鲁•沃克(Andrew Walker)表示,一些制造商正通过悄悄削减份量来应对价格压力。雷诺(Raynor)已将其客户的产品价格提高了四分之一。

“The evidence is that the era of cheap food is over,” says Tim Lang, emeritus professor of food policy at City University. For Lang, sandwich manufacture is a carbon-intensive industry, over-reliant on cheap labour. “You’ve got a plastic-wrapped sandwich made overnight in a factory up the A1 and driven down in cold store, oil-guzzling trucks to deliver to put in a BP M&S garage. Is it sensible? It’s bonkers,” he says.

城市大学(City University)食品政策荣誉教授蒂姆•朗(Tim Lang)表示:“证据表明,廉价食品的时代已经结束。”在朗看来,三明治制造是一个碳密集型产业,过度依赖廉价劳动力。“你可以在A1区的工厂里连夜制作一个塑料包装的三明治,然后用耗油量大的卡车把它送到英国石油公司玛莎百货的车库。这是明智的吗?这太疯狂了,”他说。

Walker believes the heyday of the traditional triangle sandwich is over, but for a different reason. He argues it will decline as consumers choose salads, wraps and other options that are seen as healthier.

沃克认为,传统三角三明治的鼎盛时期已经结束,但原因不同。他认为,随着消费者选择沙拉、卷饼和其他被认为更健康的食品,这一数字将会下降。

Others are more optimistic. “The core of this nation is run by . . . blue-collar workers in manufacturing. They need a sandwich on the go, they don’t have time to have dinner and they love what they love,” says Dan Silverston, managing director of The Soho Sandwich Co.

其他人则更为乐观。”这个国家的核心是由......制造业的蓝领工人经营的。他们需要随时随地的三明治,他们没有时间吃晚饭,他们喜欢他们喜欢的东西,"Soho Sandwich公司的总经理丹·西尔弗斯顿(Dan Silverston)说。

Some remote workers may be convinced to buy their packaged sandwiches close to home. Sales in Pret’s suburban London shops are now 18 per cent higher than pre-Covid levels while City stores’ sales are still around 17 per cent lower, Bloomberg data show. The motto of its current chief executive, Pano Christou, is “take Pret to the people”. But, Xiaowei Xu, senior research economist at the Institute for Fiscal Studies, expects this trend will make sandwiches more expensive “because places where people live are less dense than places where they work”.

一些远程工作者可能会被说服在离家近的地方购买包装好的三明治。彭博社的数据显示,Pret伦敦郊区商店的销售额现在比新冠疫情前高出18%,而金融城商店的销售额仍低17%左右。其现任首席执行官帕诺·克里斯托的座右铭是“把Pret带给人民”。但财政研究所(Institute for Fiscal Studies)高级经济学家徐晓伟预计,这一趋势将使三明治变得更贵,“因为人们生活的地方比他们工作的地方密度小”。

As for Raynor, he argues the sandwich will be “dragged kicking and screaming back to pre-Covid levels of variety, but that will be massively stymied by inflation . . . It will take time and customers will have to accept that the price for a sandwich will not be what it was two years ago.

至于雷诺,他认为三明治的多样性将“生龙活虎地回到新冠病毒爆发前的水平,但这将受到通胀的极大阻碍……这将需要时间,顾客将不得不接受一个事实,即三明治的价格将不再是两年前的水平。”

“Nothing else is going to stand still,” he says, “so why would the sandwich?”

他说:“没有什么东西会停滞不前,那为什么三明治会呢?”